A passion for plastics

How two students’ zeal for reuse led to Concordia’s latest sustainability initiative

Concordia’s Precious Plastic Project, or CP3, was recently granted $20,000 in funding from Concordia’s Council on Student Life.

“We believe in what we were applying for,” Sara Ordonselli, a final year mechanical engineering student, said of the sustainability initiative she co-founded. “The fact that we went from three to 30 members in a couple of months, during a pandemic, shows that students want this project on campus.”

The funding CP3 received will go towards the creation of a community space on campus, where students will be able to learn about plastics, sustainability, as well as partake in the recycling process.

Concordia’s own Sustainability Action Plan is ambitious, with a focus on food, waste, climate, research and curriculum. The university wants to play its part as the need for sustainable enterprise continues to grow.

Student initiatives will no doubt play a huge role in helping achieve these objectives, and though there is a wealth of initiatives to look to, none have perhaps grown as quickly as CP3. But what exactly is CP3? Though its growth has come recently, the project has been around for a few years, and its story starts with Ordonselli.

Ordonselli has always been fascinated by 3D printing, which is in part why she has been a part of the Canadian Society for Mechanical Engineers for several years now. She came across CP3 roughly three years ago, around the time she joined CSME.

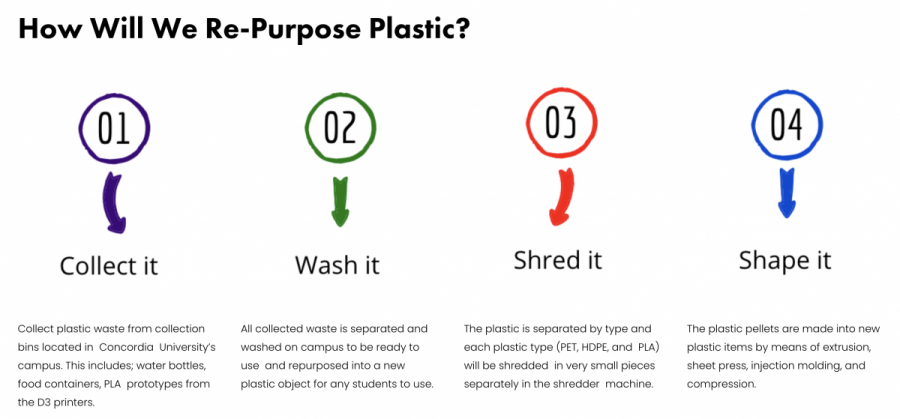

The project is a global open-source plastic recycling initiative that shares its hardware designs with anyone interested in repurposing plastic. Essentially, it consists of a series of publicly available designs of machines, which take wasted plastics and grind them into pellets. Those pellets can then be repurposed through heated or compression molding to make a number of objects, including 3D printing filament, which is the material used to make 3D printed objects, Ordonselli explained.

At the time, Ordonselli’s newfound interest in the Precious Plastic machinery, paired with her interest in 3D printing, led her and fellow CSME member Breno Hoelz Coscarelli to branch out and create CP3, an initiative which would rely on the open-source designs of the global Precious Plastic project.

“We really just wanted to implement a plastic repurposing program here, because we were just so overwhelmed with the amount of waste we were creating,” Ordonselli said.

Initially, the project was focused on the machinery necessary to repurpose plastic. “When I joined CSME, they were working on a capstone project which relied on Precious Plastic plans to manufacture the machines from scratch,” she said.

Ordonselli and Coscarelli wanted to get a couple of these machines up and running so they could begin repurposing plastic at Concordia. The aim was to reduce Concordia’s plastic waste, as well as lengthen the life of plastics used for 3D printing, which was becoming increasingly popular among students. Over time, however, the project morphed into a different niche that was just as focused on education and raising awareness as with the machinery.

“We wanted people to ask what it means to recycle, where do your items actually go once you put them in the recycling bin, and specifically what that means at Concordia,” Ordonselli explained. “We started doing club fares to get people involved, and that’s how we met Wanda.”

Wanda Stamford is also in her final year as a student, studying business technology management, with an interest in the intersection between technology and sustainability. Stamford met Ordonselli at CP3’s tabling during September 2019’s Sustainability Action Week at Concordia, and immediately got involved. From then until the start of the COVID-19 pandemic, the team of three was working to grow their club through continued club fare appearances and social media. But when the pandemic hit, CP3 was put in a difficult position.

“We weren’t doing too well, nobody really knew about us so I was worried. I thought to myself, ‘Oh my gosh, the project is gonna end,’” Stamford said.

The pandemic was set to exacerbate the already difficult challenge of getting students involved. However, being steadfast believers in the project, both Stamford and Ordonselli thought if they could do one thing every week, by the end of the summer they would have done enough to have something more concrete.

“I never thought we would've done so much,” Ordonselli said. Their simple, task-based plan had worked incredibly well. Not only were they able to grow CP3’s membership base through awareness campaigns online and construct a website, but they also developed a plan for CP3 that could see the project live on beyond their eventual graduations.

“Sustainable enterprises are growing, this isn't just a trend and we need people from all sides. We need accountants the same way we need engineering students or computer science students. This is why we decided to go with a skill-sharing, mentorship methodology,” Stamford explained.

CP3’s team is now composed of students in varying fields, all of whom provide a different perspective and expertise to the initiative. At Concordia, plastics are being used at an increasingly higher rate for 3D printing, and it isn’t restricted to any one faculty or department. If you look at plastic usage beyond its educational purposes, a vast majority of students still use plastic products on a regular basis, and they wanted their team to reflect this diversity.

By the time funding application periods for fall 2020 special projects were beginning to open, Ordonselli and Stamford, now with a structure and sizable membership base, had begun dreaming of a physical community space in which CP3 could operate at Concordia.

“The idea we have inspired by Zero Waste Concordia's recommendation is to renovate and place a shipping container at Grey Nuns, giving students an open source space where they can learn about our project, assist with the repurposing of plastic, do research and find needed materials,” Ordonselli wrote in CP3’s Concordia’s Council on Student Life special funding application.

CP3 backed themselves in applying for special funding, and it paid off. They received $20,000 from CCSL this past month, a substantial figure that puts them near their required estimate for setting up a community space at Concordia.

“I think something that helped us is that we were a club that was growing and creating engagement even when school was shutting down. We were able to showcase why students need this and just how many would willing to work with us,” Ordonselli explained.

The project itself would provide an important research opportunity, allowing students to learn about plastics and interact with them throughout the recycling process, but it’s also directly in line with Concordia’s own sustainability goals. The university is aiming for a 50 per cent reduction in its waste from landfill by 2028, and sustainability initiatives on campus will be key to achieving this, Ordonselli said.

Concordia University’s Centre for Creative Reuse, located at Grey Nuns, is an example of one of these successful sustainability initiatives. “We want to create a community of sustainability,” Ordonselli said, and a CP3 space nearby would certainly mark a step towards this goal.

Currently, the estimated cost of acquiring the shipping container, as well as all necessary modifications and renovations, sits around $28,000. Having already amassed $20,000 from CCSL, and awaiting responses from faculty funding and other grant applications, CP3 are confident they will be able to secure the money necessary to make their community space happen.

“Our aim for this semester is to have the funds necessary to make the shipping container purchase, and next semester our funding objectives are to cover the cost of machinery,” Stamford said.

“We’re trying to implement a strong structure because it’s important this project continues,” Ordonselli said. They wanted to create a model wherein CP3 could involve other passionate students such that it doesn’t need to rely solely on them.

“Our job, in many ways, has been to build this up so others can take it on from us,” Stamford added.

The skill-sharing mentorship approach certainly seems to have paid off on this front. With 36 active members, 20 of whom are doing work on a regular basis, as well as several members in coordinating roles, it’s safe to say that they have made longevity a real possibility.

CP3 managed to leverage the pandemic to propel their project to new heights, and as long as students as passionate as Stamford and Ordonselli are around, it’s mission of driving systematic change when it comes to plastic recycling and awareness will be in good hands.

A previous version of this article misspelled Breno Hoelz Coscarelli's name. The Link apologizes for this error.

_900_642_90_600_375_90_s_c1.jpg)

_600_375_90_s_c1.jpg)